Takenaka Corporation Uses Matterport Digital Twin Technology for Building Surveying, Remote Inspections, and Effective Collaboration for Construction and Facility Projects

Japanese-based construction firm uses Matterport to streamline facility management and site inspections by documenting mechanical, electrical, and plumbing conditions for efficient facility maintenance

Customer results summary:

Reduced time to produce 360-degree photographs by 90%

Saved thousands of dollars per scan by eliminating the need to use expensive laser scanners

Cut travel and labor costs through remote surveying and inspections

Breaking Into The Japanese Market

Founded in 1610, Takenaka Corporation is one of Japan's leading general constructors. Though the company has been around for more than 400 years, it prides itself in adopting cutting-edge technologies.

In 2017, Takenaka Corporation became one of the first players in Japan to adopt Matterport, Inc. 3D digital twin technology. By capturing digital twins of construction and mechanical, electrical, and plumbing (MEP) projects throughout the building lifecycle, Takenaka Corporation documents site conditions in a photorealistic and dimensionally accurate way, enabling teams to collaborate more effectively at every stage of the project.

Initially, Takenaka Corporation used conventional 3D laser scanners to capture spaces digitally, which required a lot of time for scanned data to be processed. Engineers also needed to be hired to conduct site surveys and capture these scans, which typically cost hundreds of thousands of yen per scan. With Matterport, Takenaka Corporation was able to reduce costs by using both Matterport’s Pro2 camera and its spatial data platform.

“Before Matterport became available in Japan, we researched the emerging technology and recognized that it had the potential to significantly reduce costs associated with capturing site survey images, as well as to minimize potential project delays and travel to sites by stakeholders and clients. This is why we were eager to introduce the technology into our workflow.

With the dimensionally accurate digital twins, we can analyze MEP information throughout the building lifecycle,” says Yasutomo Matsuoka, Chief Researcher, Advanced Mathematical Sciences & Informatics Group, Future & Advanced Technology Research Department, Research & Development Institute at Takenaka Corporation.

Additionally, the Matterport MatterPak Bundle allows team members to download colorized point cloud and 3D mesh files to help document as-built conditions, validate models, and design faster than ever before.

Currently, Takenaka Corporation’s on-site teams capture digital twins, so team members and clients can inspect building conditions and oversee facility management projects remotely. The company has captured digital twins of approximately 1,000 locations stored on the Matterport platform.

Masahiro Sakaue, BIM Promotion Department, whose role is to promote the latest solutions discovered by the Global Research & Innovation Team at Takenaka Corporation, explains "We introduce new technologies by hosting in-house seminars and visiting branch offices around Japan. While other new technologies are sometimes used only once and fail to penetrate, Matterport has been a rare case that has spread rapidly based on success and word of mouth."

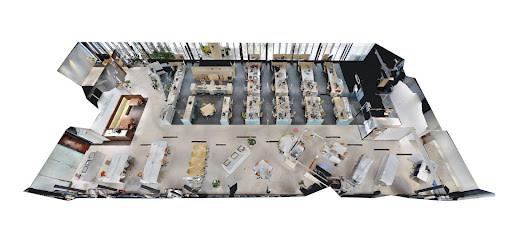

A Matterport digital twin doll-house view of the company's Higashi Kanto Branch office.

Creating An Immersive Experience Through Virtual 3D Walkthroughs

Until now, it was common to hire professional photographers to take photos once a space was completed. With Matterport’s Pro2 camera, these photographs can now be saved as high-definition 3D virtual walkthroughs. This allows users to experience the designer's attention to detail in the building's spaces and design, creating a new experience for Takenaka Corporation customers that was not possible without Matterport.

In fact, Takenaka Corporation is considering providing digital twins of completed construction to clients to increase customer satisfaction at project closeout.

Checking the Condition of Building Facilities Has Never Been Easier

For Takenaka Corporation, a major benefit of introducing Matterport in its facility management department is the time saved in preparation for repair and renovation projects.

Typically, site surveys were necessary to help facility managers assess current building conditions. These surveys usually last several days and require taking many photos, stitching them together, and measuring dimensions. Taking these pictures is also sometimes difficult, with multiple trips to the site necessary to avoid missing important parts when shooting in complex machine rooms or behind narrow ceilings.

Using Matterport Pro2 cameras to capture high-resolution digital replicas, Takenaka Corporation reduced the time previously required for taking photos by about 90%. By utilizing Matterport’s digital twin reproductions, teams were also able to reduce the hours required for planning by remotely measuring spaces without the need to be there in person.

In addition, teams can also reference these digital twins for future renovation work, so they can skip on-site surveys and proceed immediately to the renovation plan.

Remote Surveys Now Possible

Takenaka Corporation also uses digital twins to check the quality and functionality of finished construction before the project’s actual completion.

After the recent completion of a newly constructed hotel, hotel management used digital twins provided by Takenaka Corporation to train staff responsible for providing guest services and overseeing operations at the hotel.

"The inspection items covered very delicate details such as the placement and angle of cups, the way linens are folded, and the way a gown is draped, which requires highly detailed imagery for reference.

Matterport digital twins provide not only the high quality and precision to meet the needs of operations staff, but also allow overseas stakeholders to perform remote quality assurance verification, leading to significant reductions in travel and labor costs," said Mr. Matsuoka.

At a Takenka internal event that showcased technology and tools used by groups within the company, the team that presented the Matterport case study received an award for the innovative use of digital twins for virtual inspections.

Mr. Sakaue has high expectations for the technology, saying, "We will continue to share these success stories within the company and expand the range of applications."

A scene taken by Matterport 3D camera that simulates a machine depot at a training facility. The photorealistic high-definition images enhance usability.

Enabling Digital Transformation Through Easy Integration

Matterport's compatibility with Android and iOS devices has also helped further boost adoption within Takenaka Corporation’s teams.

Several years ago, Takenaka Corporation delivered iPads to all of its approximately 7,000 employees in order to promote the digitization of business operations. The free Matterport Capture app for iPhone and iPad pairs with Matterport Pro2 3D cameras, serving as a remote control with automation and making it easy to capture space and upload it to the Matterport platform.

The ability to use Matterport technology with existing equipment meant Takenaka Corporation could easily capture spaces without the need to buy additional equipment, greatly simplifying the process.

Mr. Matsuoka said: "Matterport is constantly developing new features, so I am confident that we will extend our use of the platform for providing instruction to on-site workers through the tagging and collaboration features. The use of Matterport at Takenaka Corporation will likely continue to expand infinitely.”

ABOUT TAKENAKA CORPORATION

Since 1610, Takenaka has specialized in architecture to produce a multitude of buildings that have become landmarks, and in this way, we have played a vital role in the development of our society. Architecture creates vessels to protect life and property that are at the same time social assets. These works carry the culture of their times and pass it on to future generations.

https://www.takenaka.co.jp/takenaka_e/

HEADQUARTERS: Osaka, Japan

INDUSTRY: Architecture/Engineering/Construction (AEC)

EMPLOYEES: 7,741

PRODUCTS:

Matterport Pro2 3D cameras

Leica BLK360, RICOH THETA Z1 / THETA V

SOLUTION:

Using Matterport’s high-quality and precise 3D captures of buildings, facility management teams are able to easily check past conditions during repair work and track renovation progress

Results:

Reduced time to produce 360-degree photographs by 90%

Saved thousands of dollars per scan by eliminating the need to use expensive laser scanners

Cut travel and labor costs through remote surveying and inspections