What Is Digital Twin & BIM? Use Cases Explained

Learn how digital twins help construction and design teams work even smarter and faster

For decades now, building information modeling (BIM) has been a valuable process for construction and design teams. 3D models are digital representations of physical space, which are helpful for planning and executing building projects. In recent years, digital twins — which are immersive 3D models of physical space (based on the as-built conditions)— have emerged to help teams work even smarter and faster.

While similar on the surface, BIM models and digital twins have some key differences. As we’ll explore in this article, these are two complementary technologies that can help architecture, engineering, and construction (AEC) teams across the building lifecycle — from initial planning to quality control in AEC and ongoing facilities management. Even in manufacturing, digital twin technology is breaking ground. Already Matterport is helping brands integrate the BIM process and digital twins to reshape the world of a smart building.

What is building information modeling (BIM)?

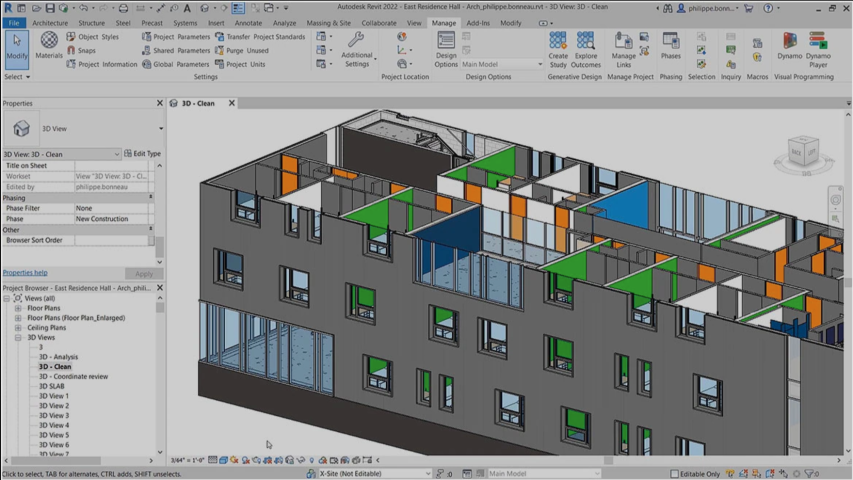

Building information modeling (BIM) is the holistic process of creating, optimizing, and managing information for a built asset from schematic design through operations. Central to the BIM process is the use of 3D models represented by the core disciplines of architectural, structural, civil/infrastructure, mechanical, electrical, and plumbing trades. These 3D models from tools like Revit, Navisworks, and Tekla are used in a wide range of industries with many different use cases but are especially central to architecture, engineering, and construction industry workflows.

Tools like Revit create dimensionally accurate detail that can be aligned to construction project coordinates to give stakeholders a central source of truth throughout the building’s life cycle. This enables more structured and streamlined project management practices from the design phase to the construction phase and onto operations.

While 3D Modeling tools have been around since the mid-2000s, the technology continues to evolve. The latest versions of the software leverage artificial intelligence to automatically create more functional data models that can integrate with the Internet of Things (IoT) devices to expose even broader application opportunities.

What is digital twin technology?

Digital twins are virtual replicas of real-world physical assets. Digital twin technology offers immersive, photorealistic 3D exploration of space that empowers collaboration between different stakeholders. This data-driven process helps teams monitor physical objects, make informed decisions, and create more efficient workflows.

Thanks to a diverse range of digital twins use cases, they are powering a digital transformation in a wide range of industries, such as construction, manufacturing, real estate, retail, and many more. They’re even powering smart cities and helping teams solve urgent supply chain difficulties. As machine learning and automation continue to strengthen digital models, this powerful technology should help even more teams navigate the project lifecycle.

What is the difference between digital twins and BIM?

Both digital twins and BIM models are digital representations of physical spaces. The main difference between the two is that BIM 3D models are used for visualizing the design and construction of an asset, while a digital twin enables virtual interaction with that asset.

More precisely, the key differences to keep in mind when talking about digital twins and BIM:

BIM models created in software like Revit represent the design intent of a building, helping to visualize the desired physical characteristics and dependencies. By themselves, the 3D models tied to a BIM process do not automatically track and represent the as-built changes over time.

Digital twins offer a photorealistic virtual rendering of physical space and can be scanned again and again over time to track how that space might change. This helps teams track milestones and gain a deep understanding of a project’s life cycle.

Digital twins integrate with IoT sensors and other digital solutions. As you use these technologies to access real-time data about your building system, digital twins act as a visual replica that accurately captures that system’s physical characteristics.

Put simply, BIM modeling software can help you design and construct a building, while digital twin technology can help you maintain and operate that building. For instance, you might use BIM modeling software to plan out where you will place a building’s HVAC system. Once you’ve built that, you’ll then use digital twins to monitor the HVAC system’s function over its life cycle.

Using digital twin and BIM across the project lifecycle

Architecture, engineering, and construction teams need a clear understanding of the built environment as they tackle major projects. Here’s how teams can use digital twin and BIM software to power better decision-making and collaboration across the project lifecycle:

Building and designing with BIM

Planning: In the planning phase of a project, conceptual design software gives teams a virtual space to brainstorm, sketch out provisional ideas, and share these ideas with teammates.

Design: If a building’s structure or dimensions need to be changed, BIM 3D models make it easy to edit building designs and solve important engineering problems.

Execution: Once it comes time to break ground on a new building, BIM 3D models give teams an overview of its constructibility. The model is a handy resource as they work to turn their virtual model into a built reality.

Managing and operating with digital twins

Model: During the building construction process, digital twins can serve as a model of your ongoing progress. As more benchmarks are completed, digital twins are updated via either recurring scans of the space or documentation like digital notes and tags so that teams always have a deep understanding of the project.

Simulate: Whether you’re using a professional-grade camera or the phone in your pocket, digital twins give you a photorealistic rendering of your physical space. Sharing these immersive digital twins with stakeholders can help them simulate what it might be like to move through that space.

Manage: With a clear view of your building, digital twins make it easy to keep up with ongoing facility management. And thanks to immersive BIM 3D models, you can virtually “visit” a space, which cuts down on costly and time-intensive site visits.

Benefits of digital twin and BIM integration

Even on their own, digital technology and 3D design software are powerful tools for teams that are designing and managing physical spaces. But when you bring them together, you can unlock powerful end-to-end control across the project life cycle. Integrating digital twin models and BIM models helps you.

Cut down on the time it takes to gather measurements and allocate resources

Quickly integrate digital scans into your company’s existing toolbelt

Operate from one central source of information — which boosts productivity, alignment, and collaboration

Reduce the travel costs and lag time that comes with frequent on-site visits

Have a visualization of your building not just at the planning phase

but across its whole lifecycle

Integrating BIM and digital twins with Matterport

Smart building requires technology that is packed with real-time dynamic insights. Digital twins can be that link that brings real-time data to your BIM project— helping you work faster and smarter. Here are a few examples that explain how Matterport can help you integrate digital twins with popular 3D design software:

Integrate with Autodesk BIM 360: San Francisco construction firm Swinerton integrated their BIM 360 software with digital twins from Matterport to give clients a chance to virtually walk through in-progress buildings. During the walkthrough, clients could flag areas that needed a second look or annotate as needed. These virtual tours improved collaboration and minimized travel costs.

Harness the power of Matterport BIM files: Canadian engineering firm HH Angus used BIM files in Matterport to give their team a shared space for collaboration during a complex mechanical engineering project. They used a digital replica to take measurements, annotate, and share progress with the client.

Place Matterport 3D models right into Autodesk Recap and Revit: London-based architecture firm Arup integrated Matterport BIM files with their existing Revit software to speed up the planning phase for their projects. This easy integration enabled them to skip the lengthy data-gathering process and create a 3D model with the click of a button.

Import models from Matterport directly into AutoCAD: KUOP Design needed a way to easily visualize their complex multi-story architectural projects. Owner David Kuoppomaki brought digital twins into AutoCAD to speed up the drafting process. With detailed, dimensionally accurate digital models, he was able to cut down on-site visits in the drafting phase of a project.